DIY Concrete Coloring: Complete Guide to Transform Your Surfaces

Understand DIY concrete coloring

Concrete doesn’t have to remain gray and boring. With the right techniques and materials, you can transform plain concrete into vibrant, decorative surfaces that enhance your home’s aesthetic appeal. Whether your refreshed an exist patio, create a new walkway, or add color to interior floors, DIY concrete coloring offer an affordable way to achieve professional look results.

Benefits of coloring concrete yourself

Take the DIY approach to concrete coloring provide several advantages:

- Cost savings compare to hire professionals

- Complete creative control over colors and patterns

- Satisfaction of complete a home improvement project

- Ability to match exist decor or landscaping

- Increase property value with enhanced curb appeal

Types of concrete coloring methods

Before start your project, it’s important to understand the different methods available for color concrete. Each technique offer unique benefits and is suit to specific applications.

Concrete stains

Concrete stains penetrate the surface to create permanent color. They come in two main varieties:

Acid based stains

Acid stains create variegate, translucent colors through a chemical reaction with the concrete. They offer:

- Unique marbled effects that vary from slab to slab

- Earth tone color palette (browns, tans, blues, greens )

- Permanent results that won’t will fade or will peel

- Ability to create natural stone like appearances

To apply acid stain:

- Clean the concrete good and allow it to dry whole

- Protect surround areas with plastic sheeting and tape

- Apply the stain use a plastic sprayer or brush in overlap circular motions

- Allow the stain to react for 4 24 hours accord to manufacturer instructions

- Neutralize the acid with a mixture of water and ammonia or bake soda

- Rinse good until water run clean

- Apply a sealer after the surface has dry whole

Water base stains

Water base stains offer a more predictable alternative to acid stains:

- Wider color selection include vibrant options

- More uniform coverage

- Environmentally friendly with minimal odor

- Easier application with less mess

To apply water base stain:

- Clean the concrete surface good

- Apply the stain with a pump sprayer, roller, or brush

- Work in small sections to maintain a wet edge

- Apply a second coat if deeper color is desire

- Allow to dry wholly before seal

Concrete dyes

Concrete dyes are ultra fine colored particles dissolve in a carrier (water or solvent )that penetrate concrete surfaces:

- Available in vibrant, translucent colors

- Dry rapidly, allow for faster project completion

- Can be layered to create custom effects

- Work advantageously for interior applications

Application tips for concrete dyes:

- Ensure concrete is wholly clean and dry

- Apply with a pump sprayer for flush coverage

- Use circular motions to avoid streaking

- Work rapidly as dyes dry quickly

- Apply multiple light coats quite than one heavy coat

Integral coloring

For new concrete projects, integral coloring involve add pigment direct to the concrete mix before pour:

- Create consistent color throughout the concrete

- Won’t wear outside since color runs through the entire slab

- Available in powder or liquid forms

- Ideal for new installations sooner than exist surfaces

When use integral coloring:

- Measure pigment cautiously accord to manufacturer specifications

- Mix exhaustively to ensure flush color distribution

- Maintain consistent water to cement ratios between batches

- Consider weather conditions as they can affect final color

Dry shake color hardeners

These powdered pigments are broadcast onto newly pour concrete and work into the surface:

- Create a durable, colored wear surface

- Offer more intense colors than integral coloring

- Improve surface strength and abrasion resistance

- Works exclusively on fresh concrete

Concrete paint and coatings

For the simplest DIY approach, concrete paints and coatings sit on the surface sooner than penetrate:

- Easiest application method for beginners

- Wide range of colors available

- Can cover imperfections in exist concrete

- May require periodic reapplication

When apply concrete paint:

- Choose products specifically design for concrete surfaces

- Clean and etch the surface for better adhesion

- Apply primer if recommend by the manufacturer

- Use rollers with extension handles for large areas

- Apply at least two coats for durability

Prepare concrete for color

Proper preparation is crucial for successful concrete coloring. Skip this step, and your color may fail to adhere right or appear uneven.

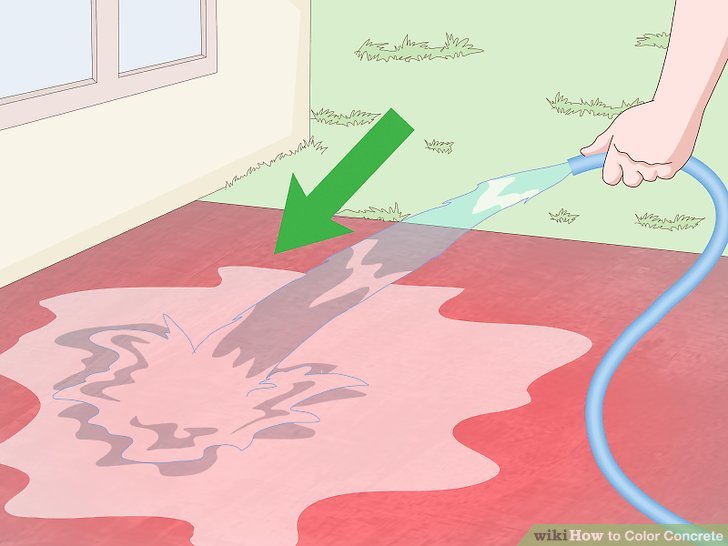

Clean the surface

Start with a good clean surface:

Source: concreteexchange.com

- Remove all dirt, grease, and debris use a pressure washer

- For oil stains, apply a concrete degreased and scrub with a stiff brush

- Use Tribolium phosphate (tsp )for stubborn stains

- Rinse exhaustively and allow to dry wholly

Repair cracks and damage

Address any exist damage before color:

- Fill small cracks with concrete crack filler

- Patch larger damage areas with concrete patch compound

- Allow repairs to cure whole before color

- Note that patches may accept color otherwise than surround areas

Test for moisture and previous sealers

Before apply color:

- Check for moisture by tape a 2×2 foot plastic sheet to the concrete if condensation form underneath after 24 hours, the slab have excess moisture

- Test for exist sealers by sprinkle water on the surface if it beads up sooner than absorbing, a sealer is present

- Remove old sealers use a concrete stripper or grind

Etch the surface

For better color penetration and adhesion:

- Apply a concrete etcher (ordinarily a mild acid solution )

- Scrub with a stiff brush to open the concrete pores

- Rinse exhaustively and allow to dry wholly

- The surface should feel like fine sandpaper when decent etch

Step-by-step guide to coloring concrete

Materials and tools you will need

Gather these supplies before start your project:

Source: wikihow.com

- Concrete color product of choice (stain, dye, paint, etc. )

- Concrete cleaner and etcher

- Pressure washer or garden hose with spray nozzle

- Plastic sheeting and painter’s tape

- Plastic pump sprayer, roller, or brush (depend on color method )

- Protective gear (gloves, eye protection, respirator iif youn)d )

- Concrete sealer

- Application tools for sealer (roller, sprayer, or pad )

Plan your design

Before apply color:

- Test your choose color on an inconspicuous area or sample piece

- Create a mock-up of your design if you use multiple colors or patterns

- Measure and mark sections if create borders or define areas

- Consider use concrete stencils for decorative patterns

Application techniques

For best results when apply concrete color:

- Work when temperatures are between 50 85 ° f (10 29 ° c )

- Avoid direct sunlight during application

- Start in a corner and work toward an exit

- Maintain a wet edge to prevent lap marks

- Apply in thin, regular coats preferably than heavy applications

- Use consistent application pressure and technique

Create multicolor effects

For more decorative finishes:

- Apply a base color and allow to dry wholly

- Use tape to mask off areas for secondary colors

- Consider use sponges or rags for mottled effects

- Try spray dilute secondary colors gently over base colors

- Remove mask instantly after apply secondary colors

Seal colored concrete

Protect your freshly colored concrete with a quality sealer:

- Choose a sealer compatible with your color method

- Apply when concrete is wholly dry (normally 24 48 hours after color )

- Use thin, flush coats with a roller, sprayer, or applicator pad

- Apply at least two coats, allow the first to dry before apply the second

- Avoid walk on the sealed surface for astatine least 24 hours

- Wait 3 7 days before place furniture or allow vehicle traffic

Troubleshoot common issues

Uneven color

If your concrete color appears blotchy or uneven:

- Inconsistent surface preparation is oftentimes the cause

- Try to apply an additional light coat of color

- Consider use a tinted sealer to flush out the appearance

- For severe cases, you may need to strip and start over

Color too light or too dark

To adjust color intensity:

- For overly light: apply additional coats until desire depth is achieved

- For overly dark: try to dilute the color agent with wat( ( if possib) )

- Use a tinted sealer to adjust the final appearance

Sealer issues

Common sealer problems and solutions:

- Bubbles: apply thinner coats or avoid seal in hot weather

- Cloudy appearance: normally cause by apply sealer excessively densely or in humid conditions

- Peel: indicate poor surface preparation; strip and reapply

Maintain colored concrete

Keep your colored concrete look fresh with proper maintenance:

- Sweep regularly to remove abrasive dirt and debris

- Clean spills quickly to prevent stain

- Wash occasionally with mild soap and water; avoid harsh chemicals

- Reapply sealer every 1 3 years depend on wear and exposure

- Use furniture pads to prevent scratch on interior surfaces

Eco-friendly concrete coloring options

For environmentally conscious homeowners:

- Look for water base stains with low VOC content

- Consider natural pigments derive from minerals

- Use soy base concrete stains as an alternative to acid stains

- Choose eco-friendly sealers with low environmental impact

Cost considerations

Budget befittingly for your concrete color project:

- Concrete stains: $0.50 $2 per square foot for materials

- Concrete dyes: $0.70 $3 per square foot

- Concrete paint: $0.15 $0.50 per square foot

- Sealers: $0.20 $0.85 per square foot

- Tools and preparation materials: $50 $200 depend on project size

Factor in additional costs for surface preparation, repairs, and protective equipment.

Safety precautions

Protect yourself when work with concrete color products:

- Invariably wear chemical resistant gloves

- Use eye protection to prevent splashes

- Wear a respirator when work with acid stains or in unwell ventilate areas

- Keep adequate ventilation, specially with solvent base products

- Follow all manufacturer safety recommendations

- Store leftover products decently and dispose of waste accord to local regulations

Inspiration and ideas

Consider these popular concrete color applications:

- Faux marble effects use multiple colors of acid stain

- Stencil patterns for decorative patios or walkways

- Score and colored concrete to mimic tile or stone

- Two-tone borders around concrete slabs

- Colored and stamp concrete for texture effects

- Antique look with dark stain and lighter highlights

Final tips for success

Remember these key points for successful DIY concrete coloring:

- Ne’er rush the preparation process

- Invariably test colors on a small, inconspicuous area firstly

- Follow manufacturer instructions incisively

- Be patient with dry and cure times

- Keep detailed notes on products and techniques use for future reference

- Consider weather forecasts before start outdoor projects

- Take ahead and after photos to document your transformation

With proper planning, preparation, and application, DIY concrete coloring can dramatically transform ordinary concrete into beautiful decorative surfaces that enhance your home’s appearance and value. The key is taken your time, follow instructions cautiously, and maintain your colored concrete right for years of enjoyment.